Loctite Conductive Inks by Henkel: Enhancing Design & Performance

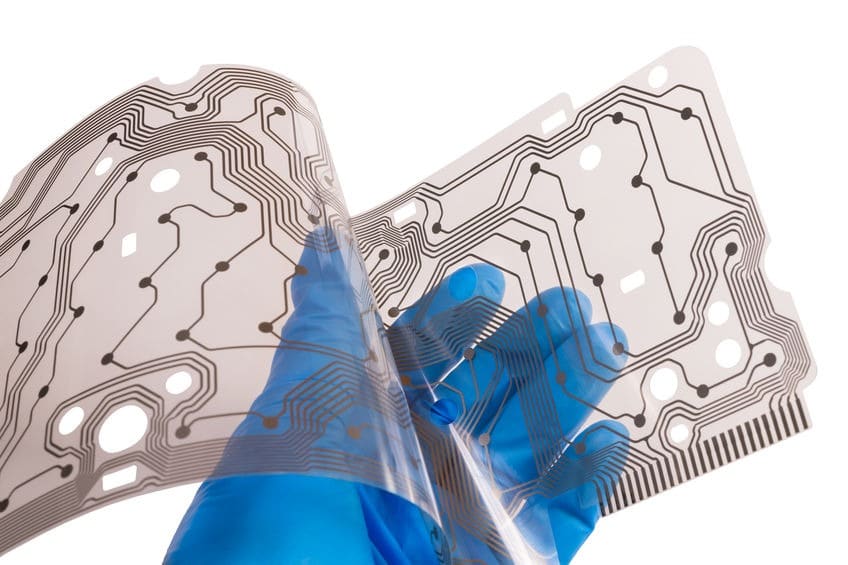

Printed electronic technologies are crucial in modern devices, providing the flexibility, functionality, and form that power a wide range of industries. Henkel’s Loctite Conductive Inks are engineered to meet the diverse needs of these applications, offering solutions for the three most widely used printing technologies: flatbed (screen/stencil), flexographic, and rotogravure printing. Loctite conductive inks ensure superior performance in the production of flexible, durable electronic circuits and components.

In addition to improving electrical conductivity, minimizing electromagnetic interference (EMI) is a critical factor in device design. For over 25 years, Loctite conductive coatings have been successfully used for EMI shielding, safeguarding sensitive electronics from interference.

Need some of our Loctite® solutions?

Go to our e-shop!

Want to check if Loctite® Conductive Inks can be a good option for you? Get in touch with us!

Loctite Printed Electronics Portfolio

Henkel’s Loctite Portfolio offers a wide range of advanced ink solutions designed for high-performance applications across various industries. Our comprehensive selection includes:

- Silver Inks – Loctite inks provide excellent electrical conductivity for quality printed circuits and components.

- Carbon Inks – These Loctite inks are ideal for low-cost applications, offering flexibility and conductivity for various substrates.

- Dielectrics – Essential Loctite inks for creating insulation layers in printed electronic devices, ensuring reliable functionality.

- Positive Temperature Coefficient (PTC) Inks – Used for temperature-sensitive applications, these Loctite inks offer self-regulating properties for enhanced safety and reliability.

- Transparent Conductive Inks – Perfect for creating transparent, conductive layers in touchscreens, displays, and other optoelectronic devices.

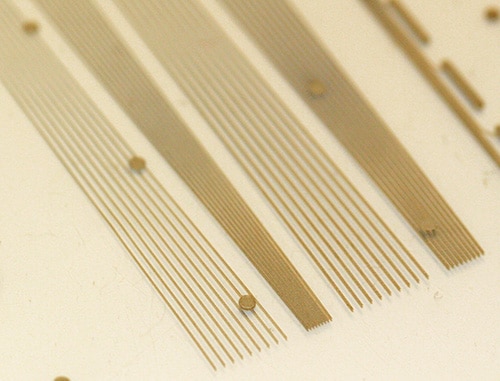

- Fine Line Silver Inks – Specially formulated for fine-line printing, these Loctite inks ensure precise and detailed circuits in small devices.

- Highly Conductive Silver Inks – Offering superior conductivity for demanding applications in medical, automotive, and consumer electronics.

- Force Sensitive Resistor (FSR) Inks – Enabling the development of sensors that detect pressure, force, or touch, perfect for interactive devices.

- Thermoformable Silver Inks – Providing the ability to form intricate shapes while maintaining optimal conductivity, ideal for flexible electronics.

Loctite Shielding Coatings: Superior EMI Protection with Premium Metallic Pigments

Henkel’s Loctite Shielding Coatings provide advanced solutions for electromagnetic interference (EMI) shielding are formulated using high-quality metallic pigments that enhance conductivity and protect sensitive electronics. The key metallic pigments used in our coatings include:

- Nickel – Offering excellent electrical conductivity and corrosion resistance, nickel-based shielding coatings are ideal for a wide range of applications, from automotive electronics to telecommunications.

- Copper – Known for its superior EMI shielding properties, copper-based coatings deliver effective protection in demanding environments, ensuring minimal interference in electronic systems.

Silver – As one of the most conductive metals, silver-based shielding coatings provide top-tier electromagnetic protection and are perfect for high-performance devices requiring the best possible shielding.

Applications of Henkel’s Loctite Conductive Inks: Empowering Advanced Electronics

Henkel’s Loctite Conductive Inks are widely used in a variety of high-performance electronics, offering superior conductivity and durability for the next generation of devices.

These inks are ideal for:

- Printed Circuits – Essential for creating reliable, flexible printed circuits in various electronic devices.

- Flexible Electronics – Perfect for wearable technology and flexible devices that require high conductivity and durability.

- Wearable Technology – Ideal for sensors and flexible circuits in wearables like fitness trackers and smart clothing.

- Medical Devices – Ensuring reliable, efficient performance in medical sensors, diagnostic tools, and health monitoring equipment.

- Automotive Sensors – Used in automotive electronics, including sensors, control units, and communication systems.

- Consumer Electronics – Perfect for applications in smartphones, tablets, smart home devices, and other electronics.

- Telecommunications Equipment – Supporting high-performance connectivity in devices like antennas and circuit boards.

- Printed Antennas – Enabling the creation of reliable, flexible printed antennas for various wireless applications.

- Smart Packaging – Providing conductivity for printed sensors and circuits in smart packaging solutions.

- Touchscreens & Interactive Displays – Enhancing the functionality and responsiveness of touchscreens and display panels.

Loctite conductive inks are also used in screen printing, flexographic, and rotogravure printing methods, making them ideal for large-scale manufacturing and precise, high-quality applications. With Loctite conductive products, industries can achieve reliable, cost-effective solutions that meet the growing demand for innovative, eco-friendly, and efficient electronic devices.

Frequently asked questions

Frequently asked questions

Resistance per square (Ohm/sq) is a measurement commonly used in the field of printed electronics to describe the electrical resistance of a thin film of material, often a conductive ink or coating, that has been applied to a substrate (such as a flexible or rigid surface). It represents the resistance of a square area of the material, regardless of its size or overall dimensions.

Here’s a breakdown of its meaning:

- Resistance is the opposition to the flow of electrical current, typically measured in Ohms.

- Per square means that the measurement is independent of the physical size of the film, and only considers the properties of the material itself. Essentially, it refers to the resistance of a unit area of the material when it is in the form of a square, typically one square inch or one square centimeter.

- Ohm/sq indicates the resistance of the material per square unit, and is often used in applications like printed circuit boards (PCBs), flexible electronics, and other thin-film technologies, where the material layer is very thin and uniform.

This measurement is useful because it allows engineers to understand the conductive properties of the material in a consistent way, regardless of the shape or size of the actual pattern or circuit they are working with. Lower Ohm/sq values indicate higher conductivity, while higher values suggest higher resistance and poorer conductivity.

The lowest track width that can be achieved with Loctite conductive inks typically depends on several factors, including the type of ink used, the printing process, and the resolution of the printing equipment. However, with Loctite conductive inks, you can achieve track widths as low as 50 microns (0.05 mm) when using fine-line silver inks and advanced printing technologies such as screen printing or flexographic printing.

For more precise applications, the exact track width may vary depending on the specific ink, substrate, and equipment capabilities, but Loctite inks are designed to offer high resolution and excellent performance for fine-line circuits and small electronics. Always consult specific product data sheets for the most accurate and up-to-date specifications for each type of conductive ink.

The lowest resistance achievable today with Henkel’s Loctite ECI 1011 can be as low as <0.003 Ohm/sq (less than 0.003 Ohm per square). This makes Loctite silver inks highly conductive and ideal for high-performance applications where low resistance and high conductivity is essential, such as in printed circuits, antennas, and other electronic components that require efficient current flow.

Want more information on Loctite Conductive inks?

Helpful product guides, tutorials or white papers will help you choose the right product. If you can’t find the answer you are looking for, do not hesitate to call us at +33 (0)1 61 44 02 90 or send an email at info@tetrachim.com.